Application Example / Industrial Plant

Application Example

Pipeline, Rotating equipment, Pressure vessel, Tank

– Degradation and damage monitoring of industrial assets (buildings, pipelines, tanks by multi-point sensor array

– Micro damage evaluation by AE methods of industrial equipments (rotating machine, tank, piping)

– Metal thickness measurement of piping

– Condition monitoring of rotating machine by AE monitoring

– Temperature and pressure measurement of piping and equipment by multi-point sensor array

Case 1

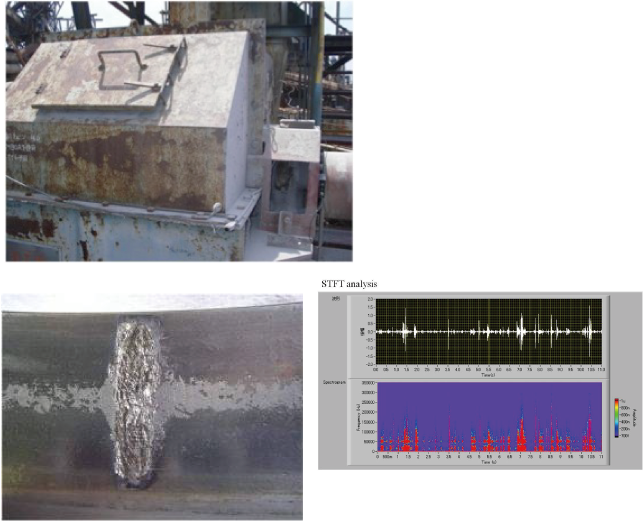

Corrosion Monitoring by AE methods

We are screening corroded area by AE methods for pipe, tower and tankages.

Case 2

Rotating machinery monitoring by AE methods

We monitor bearing and other equipments at rotating machinery by AE methods.

Case 3

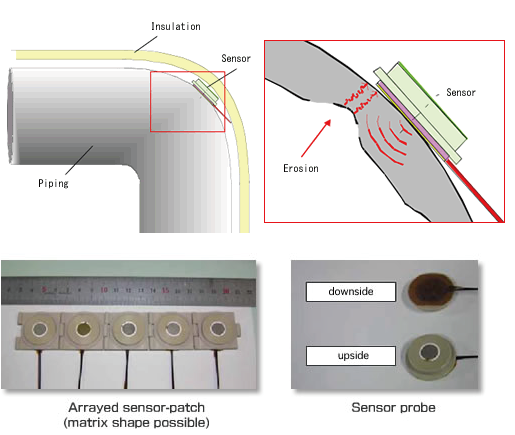

On-line metal thickness measurement of piping

By EMAT / FOD system , metal thickness can be measured “on-line” for piping maintenance with +/- 0.1mm accuracy. By this system, thickness measurement can be done during operation without disassembling insulation materials, once installed. This is totally different from conventional Ultrasonic Test and Ultrasonic thickness measurement.